Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

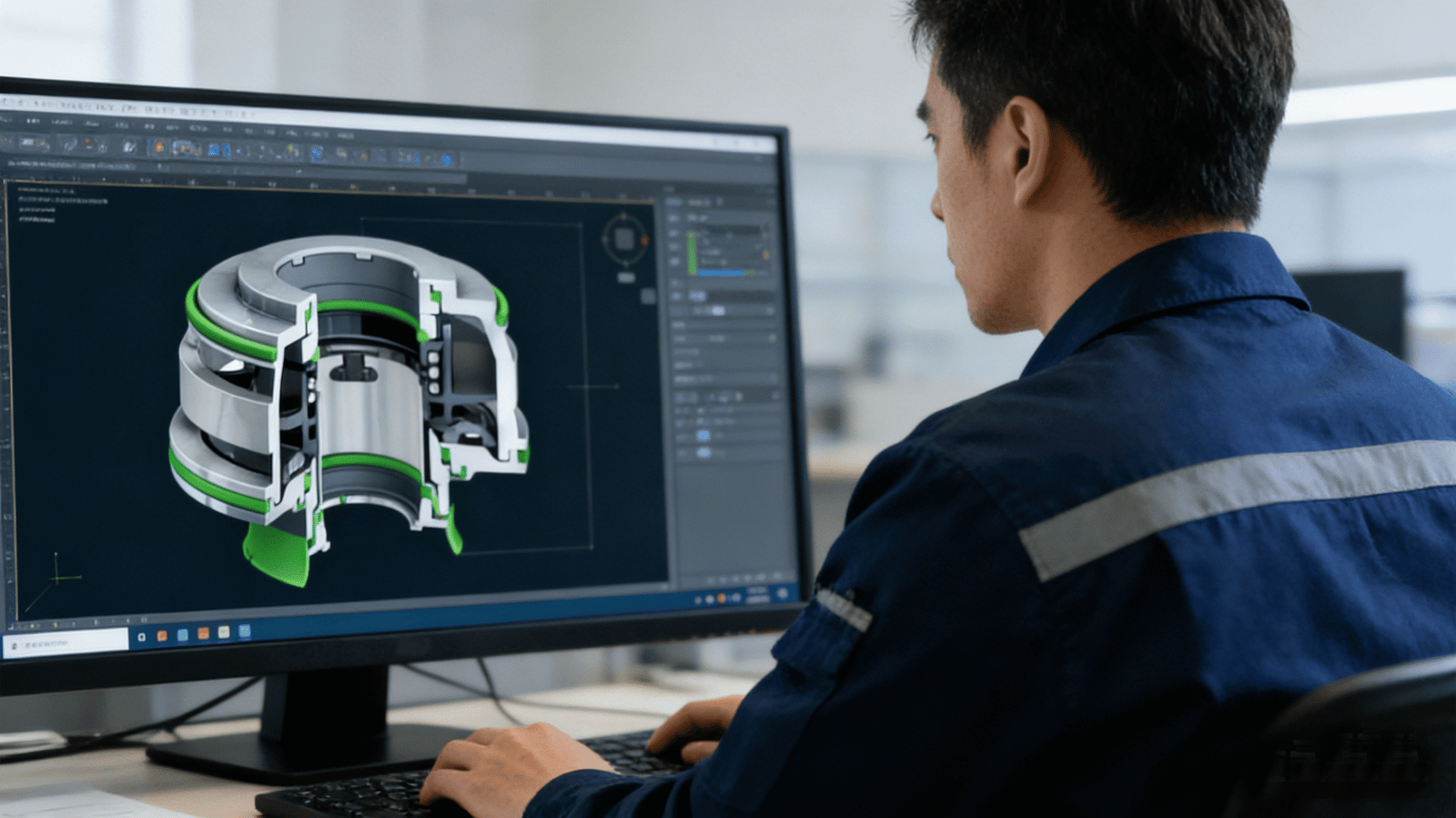

Look around you: the water from your tap, the fuel in your car, the chemicals in everyday household products—their journey from source to your home relies on a critical yet nearly invisible component: the mechanical seal. Tucked inside pumps, mixers, and compressors, these precision devices perform a quiet but vital role: stopping leaks. In a…

Our mechanical seals feature a premium, carefully selected range of sealing materials—including high-grade rubber, corrosion-resistant stainless steel, ultra-hard silicon carbide (SiC), and wear-proof tungsten carbide (TC), top quality graphite and ceramic.This versatile material portfolio is built to meet the unique demands of diverse industries, from oil and gas to pharmaceuticals and food processing. Leveraging top-tier…

When pumps exhibit leaks, efficiency loss, or unusual noise, the underlying issue is frequently a worn, damaged, or incorrectly installed mechanical seal. Our certified technicians specialize in precision pump maintenance and mechanical seal replacement—providing solutions that restore peak pump performance, extend equipment life, and reduce costly unplanned downtime. We adhere to a rigorous, industry-standard procedure…